In order to further improve the quality of products and services, and solidly promote “intrinsic safety” into the mind and heart, our company recently held special training on product quality and intrinsic safety.

Baojia Hou, chairman of the User Working Committee of China Construction Machinery Industry Association, focused on the following six aspects and analyzed the importance of quality improvement one by one.

1. Quality improvement from pass rate to survey user satisfaction

2. The concept of total quality from the perspective of management

3. The quality of the process determines the quality of the result

4. Various tasks are continuously improved in the PDCA cycle

5. How can high-level, middle-level and grass-roots work together to improve quality

6. Improve quality performance by eliminating all kinds of waste

Enterprise management is a user-centered business activity, starting with user needs and ending with user satisfaction.

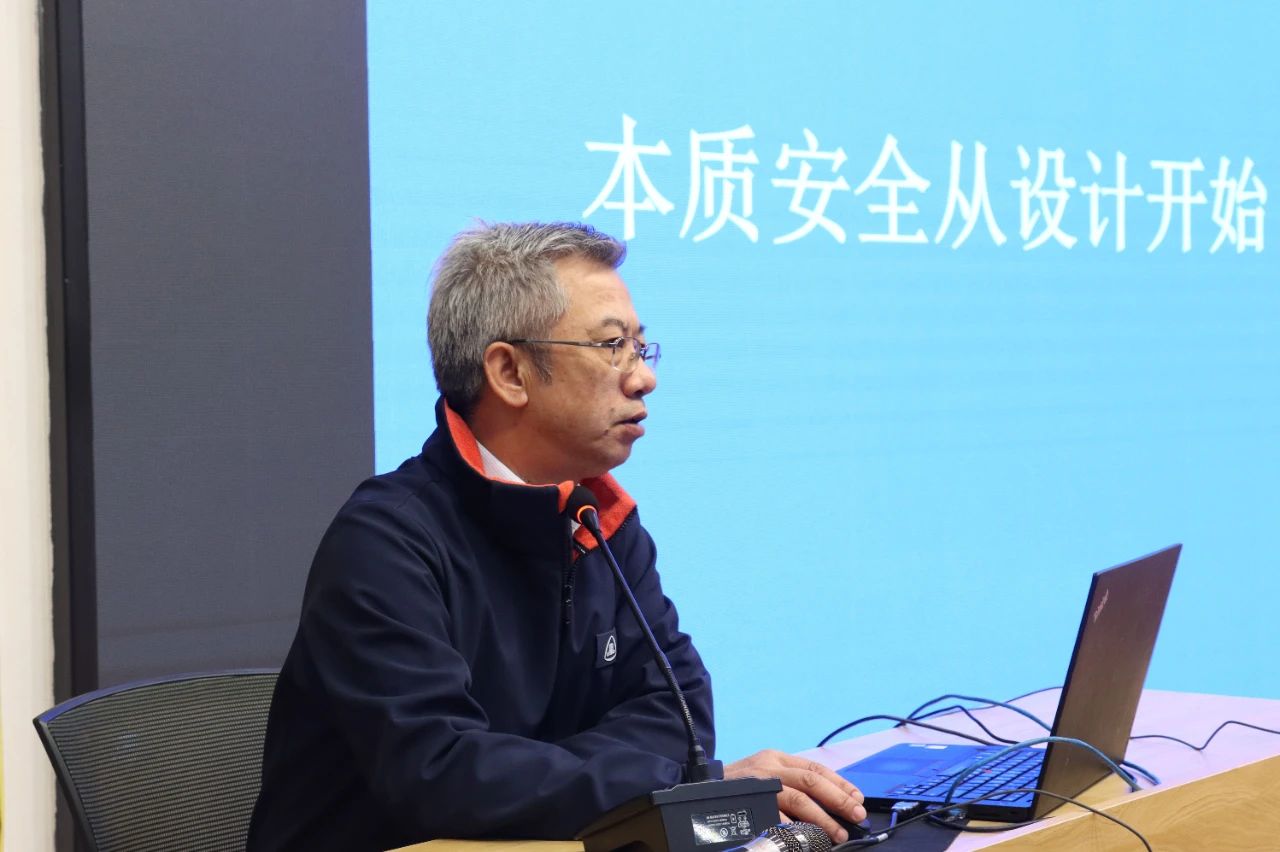

Wenlong Luo, chief engineer of the company and director of the Institute of Science and Technology Innovation, summed up years of experience in accident identification and analysis.

Centering on “intrinsic safety starts from design”, we focus on analyzing real cases on site and put forward warnings for life. Safety is a problem that designers, production personnel, installers and operators should pay close attention to. Negligence in any link may pay the price of life.

Be in awe of life and focus on intrinsic safety from design.

More than 100 members of the company’s leadership team in charge of quality and safety, heads of quality and safety-related departments, quality personnel, technical backbones, and production backbones participated in the training simultaneously at the main venue in Langfang, the branch venue in Dezhou Base, and online.