Hydraulic Vibration Hammer

V150/250/330/350/400/450/500/550

Brand JAINE

Model JV400,JV500,JVC70

Brief Introduction

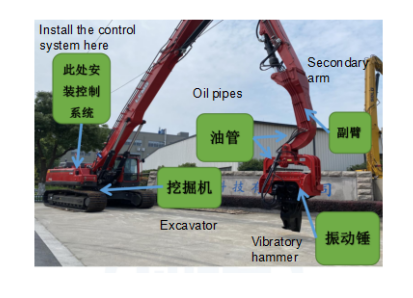

The hydraulic vibratory pile hammer for excavators (hereinafter referred to as excavator hammer) is a working device matched with the excavator, and it is one of the many attachments of the excavator.

Working method: Connected with the bucket rod, bucket connecting rod and rocker connecting rod of the excavator,it is a kind of piling machinery that uses the hydraulic power source of the excavator to work.

Working principle:Vibration hammer is a high-frequency vibration generated by high-speed rotation of eccentric wheel driven by hydraulic motor. Vibration energy is transmitted to the pile body by clamps, which changes the soil structure around the pile body and forms a fluid state. In this way, friction resistance between the pile body andsoil is reduced. Then, the pile body is sinked or pulled out of the soil by the force of excavator to complete construction work.

Scope of application: It is suitable for the construction requirements of Larsen piles, H-shaped piles, U-shaped piles, steel pipe piles and wooden piles in municipal engineering, cofferdams, pipe corridors, photovoltaics, building foundations, bridges, foundation pit support and other projects.

Equipment features: The perfect combination of the excavator hammer and the excavator gives full play to the excavator’s flexibility, small footprint, small excavator hammer, and high efficiency, to achieve the purpose of reducing construction costs and improving construction efficiency.

Application prospects: The development of excavator hammers has benefited from the rapid growth of excavator output driven by the expansion of my country’s infrastructure. As of the end of 2020, my country’s annual output of excavators has exceeded 300,000 units. Excellent mobility and durability will inevitably enable excavators to expand many other functions. After excavators are equipped with excavator hammers, they are widely used in construction, earthwork, and projects such as roads and bridges can realize piling operations in different stratums and have broad application prospects.

Excavator hammer classification

According to the structure, it is divided into two series: ordinary excavator hammer and side clamp excavator hammer.

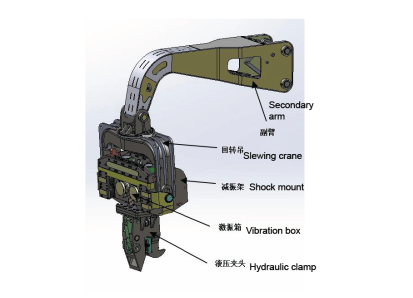

Ordinary excavator hammer

Ordinary excavator hammer is the most commonly used variety. The excavator hammer is clamped from the top of the pile to plant or pull piles. The installation of this type of excavator hammer requires modification of the excavator’s large arm, small arm,counterweight and other components,also add secondary arm. There are also restrictions on pile length.

| NO. | Parameter name | Unit | JV400 | JV500 |

| 1 | Eccentric Force | Kgm | 6 | 7 |

| 2 | Maximum frequency | rpm | 2600 | 2600 |

| 3 | Maximum vibration force | KN | 440 | 510 |

| 4 | Maximum working pressure | MPa | 31.5 | 31.5 |

| 5 | Maximum working flow | L/min | 280 | 280 |

| 6 | Total weight | Kg | 3780 | 3850 |

| 7 | Size | mm | 759×1630×3330 | 759×1630×3330 |

| 8 | Adapted excavator specifications | 25-40T | 35-50T | |

| 9 | Model of secondary arm | JA250 | JA250 |

Side clamp excavator hammer

The side clamp excavator hammer can clamp the pile from the side and top for pile planting or pulling out. In theory, there is no limit to the length (height) of the pile. The matching excavator generally does not require special modification, nor does it require secondary arm. The current market share is low, and few manufacturers produce it.

| NO. | Parameter name | Unit | JVC70 |

| 1 | Eccentric Force | Kgm | 7 |

| 2 | Maximum frequency | rpm | 2800 |

| 3 | Maximum vibration force | KN | 610 |

| 4 | Maximum working pressure | MPa | 31.5 |

| 5 | Maximum working flow | L/min | 280 |

| 6 | Total weight | Kg | 3300 |

| 7 | Size | mm | 1380×1430×2660 |

| 8 | Adapted excavator specifications | T | 35-50 |

| 9 | Model of secondary arm | / |