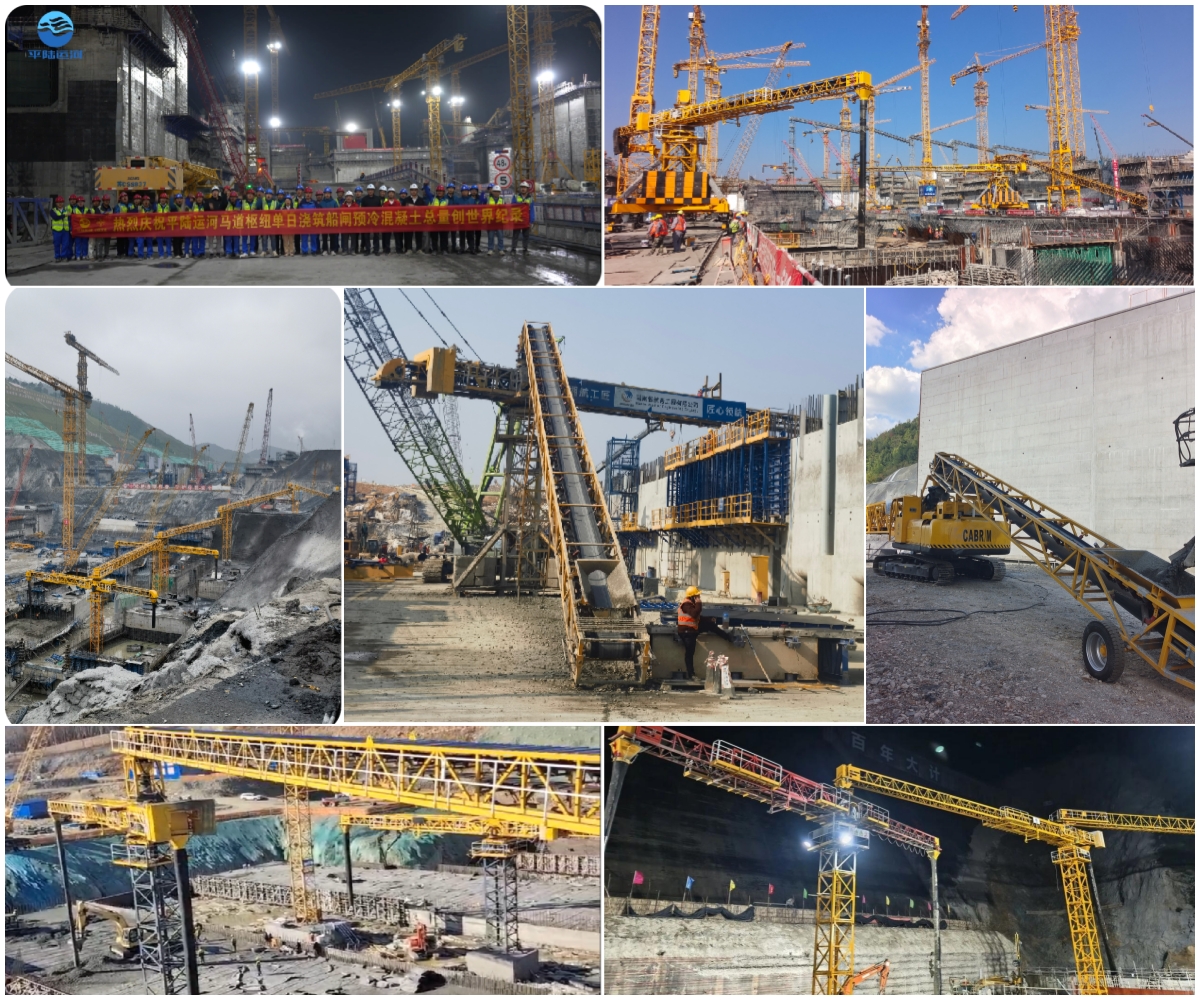

Langfang CABR Construction Machinery Technology Co.,Ltd. has developed a high-efficiency concrete delivery and pouring system to meet the urgent needs of large-scale infrastructure construction projects such as water conservancy and hydropower, wind power, railway and highway, and bridge and tunnel projects. The system has been successfully applied in a large number of projects, including the Pinglu Canal, a landmark project, and has been exported to the KKK Hydropower Station in Angola.

The system mainly includes products such as a long-distance concrete conveying and feeding line, a concrete shuttle belt pouring machine, and a vehicle-mounted telescopic belt concrete pouring machine. Each component can be integrated into the system or applied independently in various engineering scenarios.

This technology is reliable and can withstand the harsh conditions of long-term working hours and high-intensity, intensive pouring. It is applicable to all types of concrete or bulk materials, is not limited by the gradation and workability of concrete materials, has high conveying efficiency, and the conveying process has no material loss.

1. Long-distance concrete conveying and supply line

This equipment uses an ultra-long conveyor belt to transport concrete directly from the mixing plant to the pouring point of the project, providing a continuous supply of concrete materials to the final pouring equipment.

In light of the complex site conditions, a systematic solution for the installation, wiring, and synchronous lifting of mountain support columns was developed. A single-column multi-line structure for large-scale projects was developed to meet the installation requirements of the material supply line with minimal engineering work. This achieved high-reliability operation under conditions of cross-air erection, large-angle downward and upward movement, long-line synchronous lifting, and continuous operation for more than 200 hours in steep mountainous terrain. A high-efficiency concrete temperature and humidity protection structure system was also developed to strictly control the temperature rise of concrete exiting the machine.

The maximum single-line conveying capacity is 600 m³/h, with no limit on conveying distance. It can be arranged in relays according to project needs, with an allowable inclination angle of 20° for upward movement and 15° for downward movement. It is especially suitable for long-distance conveying of large volumes of concrete in water conservancy and hydropower projects such as dams and ship locks, as well as various densely populated work areas.

2. Concrete shuttle belt pouring machine

This equipment features a column-supported structure with a movable belt-driven concrete pouring machine at the top. It allows for double-end discharge and variable amplitude pouring via the belt conveyor's left-right movement. The equipment can rotate ±180 degrees, enabling full-coverage pouring within its radius. As the structure rises, the columns can be continuously heightened using self-lifting technology to meet operational needs. Various structures, including fixed and track-moving types, have been developed to suit different engineering requirements.

The equipment has a wide coverage radius, large discharge capacity, high pouring efficiency, and reliable belt conveyor operation. It is suitable for various gradations and fluid plastic hydraulic concretes. With the addition of material supply line technology, it can realize remote material supply and continuous pouring from the mixing plant to the pouring point.

The equipment has a conveying capacity of 120m³/h and a pouring radius covering multiple specifications from 20 to 30 meters, making it particularly suitable for large-volume concrete pouring construction such as water conservancy hubs, dams, and large foundations.

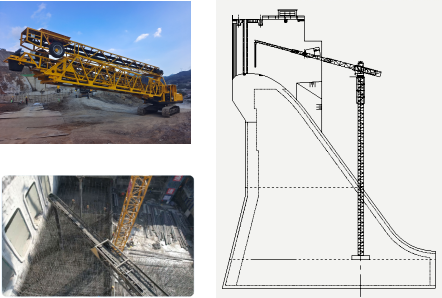

3.Telescopic Belt Concrete Pouring Machine

The pouring system of this type of equipment is a telescopic belt conveyor. Utilizing the multi-stage telescopic structure of the belt conveyor, it meets the requirements for variable-amplitude pouring and can simultaneously extend and retract while pouring. Combined with its rotation function, it can cover the entire radius of the work area. The equipment has a pitch function, which can easily achieve skip-pouring operations or cover a certain height difference range without raising or lowering the base/chassis.

Based on different operating scenarios, two types of concrete pouring machines were developed: vehicle-mounted telescopic belt concrete pouring machines and fixed telescopic belt concrete pouring machines. The former uses a self-moving tracked chassis or wheeled chassis, which can move flexibly in the horizontal plane; the latter has a fixed column support structure, which is suitable for fixed-point operation as the structure gradually rises.

The equipment has a conveying capacity of up to 200m³/h and a pouring radius of 50m. It can transport concrete of various grades and various bulk materials. The vehicle-mounted telescopic belt concrete pouring machine is widely used for mobile construction of water conservancy and hydropower projects, dams, wind power foundations, as well as highways, railways, bridges and other projects. The fixed telescopic type is mainly suitable for the construction of water conservancy and hydropower projects, dams and other projects, and is especially suitable for operations in densely populated areas or in scenarios where vehicle-mounted equipment is not suitable.

4.Representative Engineering Cases